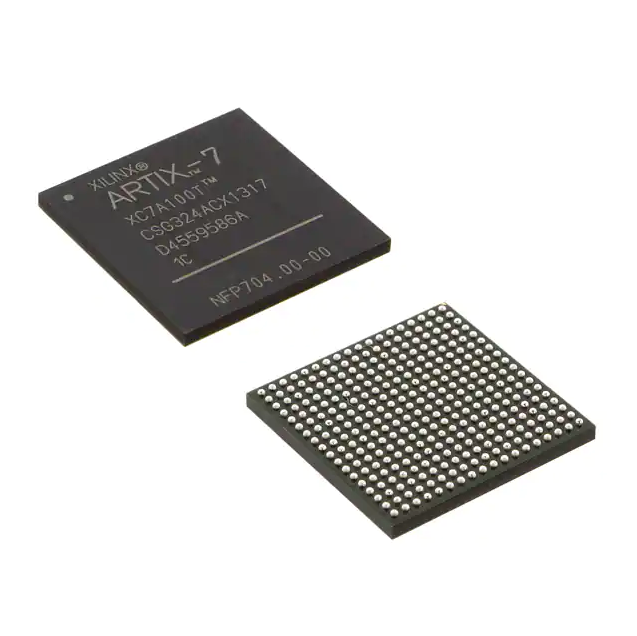

Semiconductor Ibikoresho bya elegitoronike TPS7A5201QRGRRQ1 Ic Chips BOM serivisi Umwanya umwe kugura

Ibiranga ibicuruzwa

| UBWOKO | GUSOBANURIRA |

| Icyiciro | Inzira zuzuye (IC) |

| Mfr | Ibikoresho bya Texas |

| Urukurikirane | Imodoka, AEC-Q100 |

| Amapaki | Tape & Reel (TR) Kata Tape (CT) Digi-Reel® |

| SPQ | 3000T & R. |

| Imiterere y'ibicuruzwa | Bikora |

| Iboneza Ibisohoka | Ibyiza |

| Ubwoko Ibisohoka | Guhindura |

| Umubare w'abashinzwe kugenzura | 1 |

| Umuvuduko - Iyinjiza (Max) | 6.5V |

| Umuvuduko - Ibisohoka (Min / Bishyizweho) | 0.8V |

| Umuvuduko - Ibisohoka (Max) | 5.2V |

| Umuvuduko w'amashanyarazi (Max) | 0.3V @ 2A |

| Ibiriho - Ibisohoka | 2A |

| PSRR | 42dB ~ 25dB (10kHz ~ 500kHz) |

| Kugenzura Ibiranga | Gushoboza |

| Ibiranga Kurinda | Kurenza Ubushyuhe, Guhindura Polarite |

| Gukoresha Ubushyuhe | -40 ° C ~ 150 ° C (TJ) |

| Ubwoko bwo Kuzamuka | Umusozi |

| Ipaki / Urubanza | 20-VFQFN Yerekanwe Pad |

| Ibikoresho byo gutanga ibikoresho | 20-VQFN (3.5x3.5) |

| Umubare wibicuruzwa shingiro | TPS7A5201 |

Incamake ya chip

(i) Chip ni iki

Inzira ihuriweho, mu magambo ahinnye nka IC;cyangwa microcircuit, microchip, chip nuburyo bwumuzunguruko muto (cyane cyane ibikoresho bya semiconductor, ariko nanone ibice bya pasiporo, nibindi) muri electronics, kandi akenshi bikozwe hejuru yubuso bwa semiconductor.

(ii) Uburyo bwo gukora chip

Igikorwa cyuzuye cyo guhimba chip kirimo gushushanya chip, guhimba wafer, guhimba paki, no kugerageza, muribwo buryo bwo guhimba wafer bugoye cyane.

Ubwa mbere ni chip igishushanyo, ukurikije ibisabwa byashushanyije, ibyakozwe "icyitegererezo", ibikoresho fatizo bya chip ni wafer.

Wafer ikozwe muri silicon, itunganijwe kuva kumusenyi wa quartz.Wafer nikintu cya silicon cyejejwe (99,999%), hanyuma silikoni yera ikozwe mumashanyarazi ya silicon, ihinduka ibikoresho byo gukora quartz semiconductor kumuzunguruko uhuriweho, ugacibwa muri wafer kugirango ukore chip.Umuyoboro woroheje, nigiciro cyibicuruzwa, ariko niko bisaba inzira.

Igikoresho cya Wafer

Ipfunyika ya Wafer irwanya okiside nubushyuhe kandi ni ubwoko bwabafotora.

Wafer Photolithography iterambere no guterana

Urujya n'uruza rw'ibikorwa bya fotolitografiya bigaragara ku gishushanyo gikurikira.Ubwa mbere, urwego rwabafotora rushyirwa hejuru ya wafer (cyangwa substrate) hanyuma rwumishwa.Nyuma yo gukama, wafer yimurirwa mumashini ya lithographie.Umucyo unyuzwa mumasike kugirango ushushanye igishushanyo kuri mask kuri fotoreziste hejuru ya wafer, bigafasha kwerekana no gukurura reaction ya fotokome.Wafers yashyizwe ahagaragara noneho itekwa kunshuro ya kabiri, izwi nko guteka nyuma yo gutekwa, aho reaction ya fotokimike iba yuzuye.Ubwanyuma, uwatezimbere yatewe kumufotozi hejuru ya wafer kugirango atezimbere icyitegererezo.Nyuma yiterambere, igishushanyo kuri mask gisigara kumafoto.

Gufata, guteka, no kwiteza imbere byose bikorwa mugutezimbere screed kandi kwerekanwa bikorwa mumafoto.Iterambere rya screed hamwe nimashini ya lithographie muri rusange ikorerwa kumurongo, hamwe na wafer yimurwa hagati yimashini na mashini ukoresheje robot.Sisitemu yose yo kumenyekanisha no kwiteza imbere irafunzwe kandi wafers ntabwo ihura neza n’ibidukikije kugira ngo igabanye ingaruka z’ibintu byangiza ibidukikije ku mafoto ya fotora na fotokome.

Doping hamwe n'umwanda

Kwinjiza ion muri wafer kugirango ubyare igice cya P na N gihwanye na semiconductor.

Ikizamini cya Wafer

Nyuma yuburyo buvuzwe haruguru, hashyizweho uruzitiro rwibice kuri wafer.Ibiranga amashanyarazi kuri buri rupfu birasuzumwa hifashishijwe ikizamini cya pin.

Gupakira

Wafers yakozwe irakosowe, ihambiriwe kumapine, kandi ikozwe mubipaki bitandukanye ukurikije ibisabwa, niyo mpamvu intoki imwe ya chip ishobora gupakirwa muburyo butandukanye.Kurugero, DIP, QFP, PLCC, QFN, nibindi.Hano bigenwa cyane cyane nubukoresha bwa porogaramu, ibidukikije, imiterere yisoko, nibindi bintu bifatika.

Kwipimisha, gupakira

Nyuma yuburyo buvuzwe haruguru, umusaruro wa chip urarangiye.Iyi ntambwe nugupima chip, kuvanaho ibicuruzwa bifite inenge no kubipakira.

Isano iri hagati ya wafer na chip

Chip igizwe nibikoresho birenga kimwe cya kabiri.Semiconductor muri rusange ni diode, triode, imiyoboro yumurima, imbaraga nke zirwanya ingufu, inductors, capacator, nibindi.

Ni ugukoresha uburyo bwa tekiniki kugirango uhindure ubunini bwa electroni yubusa muri atome nucleus mu iriba ryizengurutsa kugirango uhindure imiterere yumubiri wa atome kugirango ubyare umusaruro mwiza cyangwa mubi wa benshi (electron) cyangwa bake (umwobo) kugeza shiraho ibice bitandukanye.

Silicon na germanium bikunze gukoreshwa ibikoresho bya semiconductor kandi imitungo yabo nibikoresho biraboneka byoroshye kubwinshi kandi ku giciro gito cyo gukoresha muri tekinoroji.

Wafer ya silicon igizwe numubare munini wibikoresho bya semiconductor.Imikorere ya semiconductor, birumvikana, gukora uruziga nkuko bisabwa no kubaho muri wafer ya silicon.