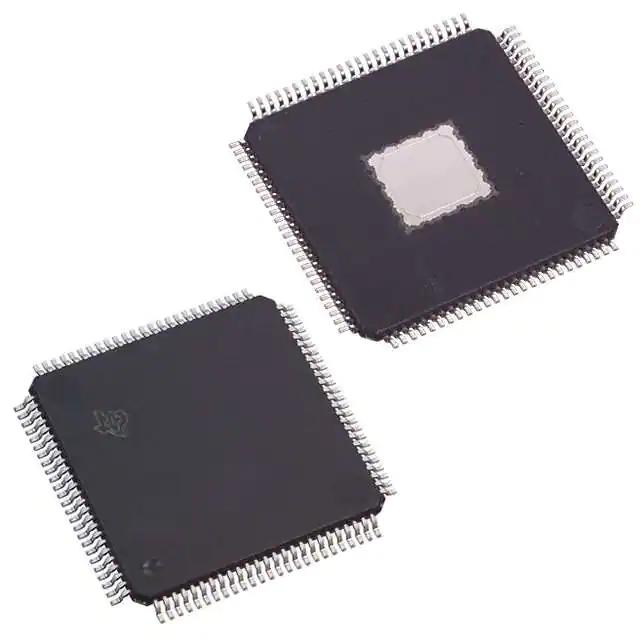

Ibirango bishya byukuri byumwimerere IC ububiko bwa elegitoronike Ic Chip Inkunga BOM Service DS90UB953TRHBRQ1

Ibiranga ibicuruzwa

| UBWOKO | GUSOBANURIRA |

| Icyiciro | Inzira zuzuye (IC) |

| Mfr | Ibikoresho bya Texas |

| Urukurikirane | Imodoka, AEC-Q100 |

| Amapaki | Tape & Reel (TR) Kata Tape (CT) Digi-Reel® |

| SPQ | 3000T & R. |

| Imiterere y'ibicuruzwa | Bikora |

| Imikorere | Serializer |

| Igipimo cyamakuru | 4.16Gbps |

| Ubwoko bwinjiza | CSI-2, MIPI |

| Ubwoko Ibisohoka | FPD-Ihuza III, LVDS |

| Umubare Winjiza | 1 |

| Umubare w'Ibisohoka | 1 |

| Umuvuduko - Gutanga | 1.71V ~ 1.89V |

| Gukoresha Ubushyuhe | -40 ° C ~ 105 ° C. |

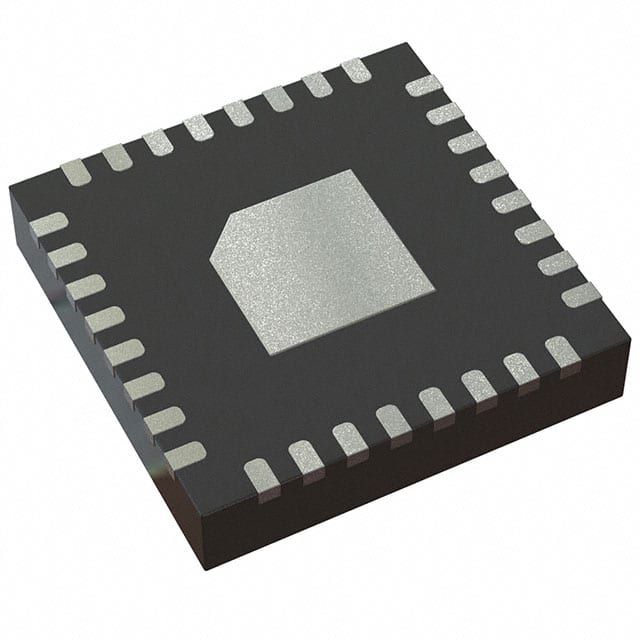

| Ubwoko bwo Kuzamuka | Umusozi wubuso, Uruhande rushyushye |

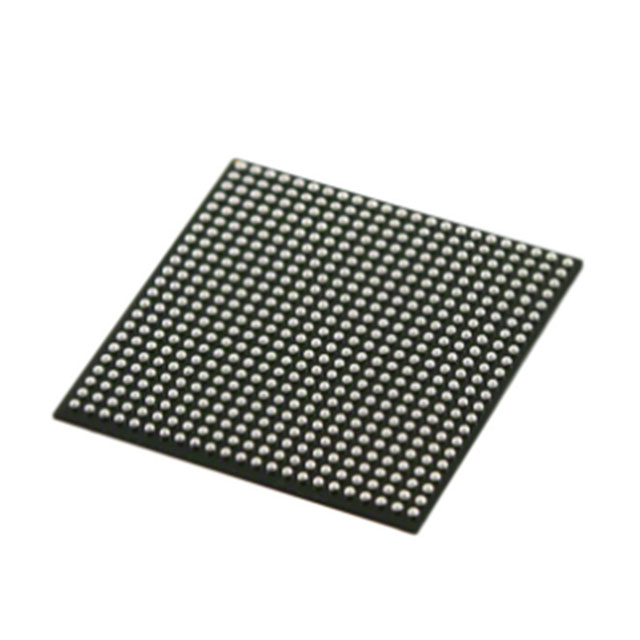

| Ipaki / Urubanza | 32-VFQFN Yerekanwe Pad |

| Ibikoresho byo gutanga ibikoresho | 32-VQFN (5x5) |

| Umubare wibicuruzwa shingiro | DS90UB953 |

1.Kubera iki silikoni ya chip?Hari ibikoresho bishobora kubisimbuza ejo hazaza?

Ibikoresho bibisi bya chip ni wafer, bigizwe na silicon.Hariho kwibeshya ko "umucanga ushobora gukoreshwa mugukora chip", ariko siko bimeze.Ibice nyamukuru bigize imiti yumucanga ni dioxyde ya silicon, kandi igice kinini cyimiti yibirahuri na wafer na dioxyde ya silicon.Itandukaniro ariko, nuko ikirahuri ari silikoni polycrystalline, kandi gushyushya umucanga mubushyuhe bwinshi bitanga silikoni polycristine.Ku rundi ruhande, Wafers ni silikoni ya monocrystalline, kandi niba ikozwe mu mucanga igomba kurushaho guhindurwa ikava kuri silikoni ya polycristaline ikajya kuri silikoni ya monocrystalline.

Niki mubyukuri silicon nimpamvu ishobora gukoreshwa mugukora chip, tuzabigaragaza muriki kiganiro umwe umwe.

Ikintu cya mbere dukeneye gusobanukirwa nuko ibikoresho bya silicon atari ugusimbuka kuntambwe ya chip, silikoni itunganijwe kuva kumusenyi wa quartz ivuye mubintu bya silicon, element ya proticon numero ya element aluminium imwe, kuruta fosifore imwe munsi , ntabwo ari ishingiro ryibikoresho bya mudasobwa bigezweho gusa ahubwo ni abantu bashaka ubuzima bw’isi ku isi kimwe mu bintu by'ibanze bishoboka.Mubisanzwe, iyo silikoni isukuwe ikanonosorwa (99,999%), irashobora gukorerwa mumashanyarazi ya silicon, hanyuma igacibwa muri wafer.Umuhengeri woroshye, nigiciro cyo gukora chip, ariko niko ibisabwa murwego rwo gukora chip.

Intambwe eshatu zingenzi muguhindura silicon muri wafers

By'umwihariko, guhindura silikoni muri wafer irashobora kugabanywamo intambwe eshatu: gutunganya silikoni no kwezwa, gukura kwa kirisiti imwe ya kirisiti, no gukora wafer.

Muri kamere, silikoni isanzwe iboneka muburyo bwa dioxyde ya silikatike cyangwa silikoni mumucanga na kaburimbo.Ibikoresho fatizo bishyirwa mu itanura ryamashanyarazi kuri 2000 ° C kandi imbere yisoko ya karubone, kandi ubushyuhe bwo hejuru bukoreshwa mugukora dioxyde ya silicon hamwe na karubone (SiO2 + 2C = Si + 2CO) kugirango ubone silikoni yo mu rwego rwa metallurgie ( ubuziranenge hafi 98%).Nyamara, ubu bwera ntibuhagije mugutegura ibikoresho bya elegitoroniki, bigomba rero kurushaho kwezwa.Silicon yo mu rwego rwa metallurgical yamenaguwe ihindurwamo chloride ya hydrogène ya gaze ya hydrogène kugirango itange silane y'amazi, hanyuma ikayungurura kandi ikagabanywa na chimique nuburyo butanga polysilicon yuzuye kandi ifite ubwiza bwa 99.9999999999% nka silikoni yo mu rwego rwa elegitoroniki.

Nigute ushobora kubona silicon ya monocrystalline muri silicon polycrystalline?Uburyo bukunze kugaragara nuburyo bwo gukurura butaziguye, aho polysilicon ishyirwa muri quartz ikomeye kandi igashyuha hamwe nubushyuhe bwa 1400 ° C ifatirwa kuri peripheri, ikabyara polysilicon.Byumvikane ko, ibyo bibanzirizwa no gushiramo imbuto ya kirisiti hanyuma ukagira inkoni yo gushushanya itwara imbuto ya kirisiti mu cyerekezo gitandukanye mugihe gahoro gahoro kandi igahagarara hejuru hejuru ya silicon yashonga.Policrystalline silicon yashonga ifata munsi yimbuto ya kirisiti hanyuma igakura hejuru yerekeza mu cyerekezo cyimbuto ya kirisiti, nyuma yo gukururwa no gukonjeshwa ikura mu kabari kamwe kamwe kerekana icyerekezo kimwe na kristu y'imbere.Ubwanyuma, waferi imwe-ya kirisiti iranyeganyega, igacibwa, hasi, irashwanyaguzwa, kandi ikoze neza kugirango itange ibyingenzi byose byingenzi.

Ukurikije ubunini bwaciwe, wafer ya silicon irashobora gushyirwa mubice 6 ", 8", 12 ", na 18".Ninini yubunini bwa wafer, chip nyinshi zirashobora gucibwa muri buri wafer, kandi nigiciro gito kuri chip.

2.Intambwe eshatu zingenzi muguhindura silicon muri wafers

By'umwihariko, guhindura silikoni muri wafer irashobora kugabanywamo intambwe eshatu: gutunganya silikoni no kwezwa, gukura kwa kirisiti imwe ya kirisiti, no gukora wafer.

Muri kamere, silikoni isanzwe iboneka muburyo bwa dioxyde ya silikatike cyangwa silikoni mumucanga na kaburimbo.Ibikoresho fatizo bishyirwa mu itanura ryamashanyarazi kuri 2000 ° C kandi imbere yisoko ya karubone, kandi ubushyuhe bwo hejuru bukoreshwa mugukora dioxyde ya silicon hamwe na karubone (SiO2 + 2C = Si + 2CO) kugirango ubone silikoni yo mu rwego rwa metallurgie ( ubuziranenge hafi 98%).Nyamara, ubu bwera ntibuhagije mugutegura ibikoresho bya elegitoroniki, bigomba rero kurushaho kwezwa.Silicon yo mu rwego rwa metallurgical yamenaguwe ihindurwamo chloride ya hydrogène ya gaze ya hydrogène kugirango itange silane y'amazi, hanyuma ikayungurura kandi ikagabanywa na chimique nuburyo butanga polysilicon yuzuye kandi ifite ubwiza bwa 99.9999999999% nka silikoni yo mu rwego rwa elegitoroniki.

Nigute ushobora kubona silicon ya monocrystalline muri silicon polycrystalline?Uburyo bukunze kugaragara nuburyo bwo gukurura butaziguye, aho polysilicon ishyirwa muri quartz ikomeye kandi igashyuha hamwe nubushyuhe bwa 1400 ° C ifatirwa kuri peripheri, ikabyara polysilicon.Byumvikane ko, ibyo bibanzirizwa no gushiramo imbuto ya kirisiti hanyuma ukagira inkoni yo gushushanya itwara imbuto ya kirisiti mu cyerekezo gitandukanye mugihe gahoro gahoro kandi igahagarara hejuru hejuru ya silicon yashonga.Policrystalline silicon yashonga ifata munsi yimbuto ya kirisiti hanyuma igakura hejuru yerekeza mu cyerekezo cyimbuto ya kirisiti, nyuma yo gukururwa no gukonjeshwa ikura mu kabari kamwe kamwe kerekana icyerekezo kimwe na kristu y'imbere.Ubwanyuma, waferi imwe-ya kirisiti iranyeganyega, igacibwa, hasi, irashwanyaguzwa, kandi ikoze neza kugirango itange ibyingenzi byose byingenzi.

Ukurikije ubunini bwaciwe, wafer ya silicon irashobora gushyirwa mubice 6 ", 8", 12 ", na 18".Ninini yubunini bwa wafer, chip nyinshi zirashobora gucibwa muri buri wafer, kandi nigiciro gito kuri chip.

Kuki silicon ari ibikoresho bibereye gukora chip?

Mubyukuri, semiconductor zose zirashobora gukoreshwa nkibikoresho bya chip, ariko impamvu nyamukuru zituma silicon aribikoresho bibereye byo gukora chip nibi bikurikira.

1, ukurikije urutonde rwibintu byisi byisi, muburyo: ogisijeni> silicon> aluminium> icyuma> calcium> sodium> potasiyumu ...... irashobora kubona ko silicon iri kumwanya wa kabiri, ibiyikubiyemo ni binini, binemerera Uwiteka chip kugira ibikoresho hafi ya byose bidashira.

2, ibikoresho bya silicon nibintu bya chimique nibintu bifatika birahagaze neza, transistor ya mbere ni ugukoresha ibikoresho bya semiconductor germanium kugirango ikore, ariko kubera ko ubushyuhe burenze 75 ℃, ubwikorezi buzaba impinduka nini, bukozwe mumasangano ya PN nyuma yinyuma kumeneka kwa germanium kuruta silikoni, guhitamo rero ibintu bya silicon nkibikoresho bya chip birakwiriye;

3, tekinoroji ya silicon ikora neza irakuze, kandi igiciro gito, muri iki gihe kweza silicon birashobora kugera kuri 99.9999999999%.

4, ibikoresho bya silicon ubwabyo ntabwo ari uburozi kandi ntacyo bitwaye, nimwe mumpamvu zingenzi zituma ihitamo nkibikoresho byo gukora chip.

.png)